Recently I posted a blog entitled ‘Animal Wastes: An Energy Resource That Is Win-Win’. The Washington Post article reproduced below may be considered a follow-up to that blog but focused on using human wastes to generate energy. It usefully points out the several beneficial uses to which human wastes can be put and the economic benefits of doing so. It is worth reading!

…………………………………

WASTE, NOT WASTED

By Ashley Halsey III

Washington Post (April 6, 2014)

This is a topic that one must approach delicately so as not to offend the reader’s sensibilities, but since it is a matter of importance for which you may receive a bill for some portion of $470 million, we start out with an analogy.

You need energy, so you eat. Through the miracle of digestion, your body sorts what you have eaten, say, a pastrami on rye with a glob of coleslaw and a dill pickle, and plucks out the nutrients — proteins, carbohydrates and sugars it needs to generate power. Then it jettisons the rest.

What your body jettisons disappears forever, carried along in a huge network of sewers to a plant in the southeastern corner of Washington.

Just like you, that plant needs energy. Through a miracle called thermal hydrolysis, it soon will be able to sort through what you have jettisoned and use it to generate electricity.

Yes, from poop will come power — 13 megawatts of it. Enough electricity to light about 10,500 homes.

Ben Franklin never dreamed of this one.

While Ben may have denounced the scheme as impossible sorcery, he also noted that a penny saved is a penny earned, so he might have been at least intrigued by this notion.

More than a few pennies may be saved for the citizens of the District and for some Virginians and Marylanders. Those people — 2.2 million of them — get a monthly bill for the privilege of sending their thoroughly digested nutritional intake to the plant in Southeast Washington operated by D.C. Water.

A chunk of that monthly bill is passed on to another local utility — Pepco. D.C. Water is the electricity company’s No. 1 customer. By converting poop to power, the water company will cut its Pepco bill by about one third and reduce by half the cost of trucking treated waste elsewhere.

But enough about poop, a subject that makes many a reader a bit squeamish. Because we’d rather not drive you away from the description of a wholly remarkable plan that is very likely to affect your pocketbook, henceforth we will refer to the matter that flows through the sewage plant as “the product.”

In fact, you soon will learn, it is going to be turned into a genuine product. One with a price tag. One that you may buy back.

Think about it.

The product has shed the label “wastewater” to morph into something called “enriched water,” a term laden with many more intriguing possibilities.

“It could be a game changer for energy,” said George Hawkins, an environmentalist who became general manager of D.C. Water. “If we could turn every enriched-water facility in the United States into a power plant, it would become one of the largest sectors of clean energy that, at the moment, is relatively untapped.”

What’s nearing completion outside Hawkins’s office window, however, is something never built on this scale anywhere in the world. A decade of study came first, and to see whether the system would work here, D.C. Water paid smaller European utilities that use the same process to modify their product so it more closely matched that which Washington produces.

“We’re confident that this model will work,” Hawkins said.

Something called the Cambi, for the Norwegian company that builds it, sits at the heart of it.

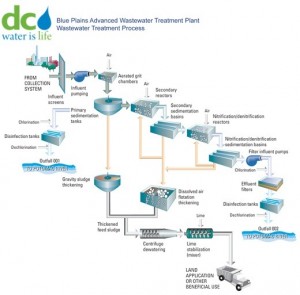

When the product flows into the more than 150-acre plant known as Blue Plains, it goes through a couple of mesh filters to shed the debris swept up in the sewer system. Then it goes through a treatment process that turns it into what the Environmental Protection Agency categorizes as class B waste, enough to fill 60 big dump trucks with 1,600 tons of product every day.

And out the gate it goes, at a cost of $16 million a year.

That will change in May and June, as D.C. Water begins a phase-in intended to get the new system into full service by January.

Here’s how it works:

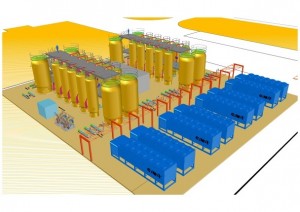

A centrifuge drains off the liquid, and then the screened product will flow into four pulpers, tall stainless steel vats that look like Gulliver’s soda cans. Steam recycled from farther down the process is used to preheat it, and then it flows into one of the two dozen Cambis. They sit like a row of gleaming, blunt-nosed rockets, but they serve as pressure cookers.

The product is heated to more than 320 degrees under as much as 138 pounds of pressure for 22 minutes. Then it moves to a flash tank, where the temperature and pressure drop dramatically and a critical change takes place.

“Because of that pressure difference, the cells burst,” said Chris Peot, director of resource recovery at D.C. Water.

When the cells burst, the methanogens can have their way with them.

That happens in the digesters. They are four huge concrete vats, 80 feet tall and 100 feet in diameter. Right now, their interiors are like vast cathedrals, with domed ceilings and a shaft of light glancing through a hole in the top.

When the whole operation gets rolling, inside them is not a place you would want to be. The product will flow in from the four flash tanks, mixing with the methanogen microorganisms. Methanogens create marsh gases. In the digestive tracts of animals and humans, they also create gas, to the particular delight and fascination of middle-school boys.

That’s what this is all about — creating methane to generate electric power.

The temperature inside the digesters is kept at about that of the human body: 98.6 degrees Fahrenheit. Each digester chamber has five vertical blue tubes, as big around as manhole covers, that suck the product from the bottom and recycle it to near the top. After the product stews there for about two weeks, the methane produced by the process will vent out a 12-inch diameter pipe in the crown.

After a bit more purification, the methane will be used to fire three jet turbine engines that create electricity. A byproduct of that process: steam, which is funneled back to the pulper.

The power portion of the plant will be operated under contract by Pepco. The deal doesn’t allow D.C. Water to sell the power it generates, a moot point since the process of creating it eats up 3 megawatts and the remaining 10 megawatts will be sucked up by operations at Blue Plains.

Once the digester’s work is done, the remaining product will be drained out into dump trucks, but their total load will be cut in half to about 600 tons a day.

Remember that we told you earlier that what you jettison disappears forever? Let’s reconsider that, because there’s actually a chance you’ll see it again. In a strikingly different form. Right back where you saw it first: on your dinner table.

The product that has been trucked from Blue Plains is rated class B. But the product that comes out of the digester will be rated class A.

The difference?

Class B still has some bad stuff in it. Most of it is shipped to farmers, some in Maryland but most of them in Virginia. They get it free, but unless they let it sit for at least a month, and sometimes up to 18 months, the only things they can use it to fertilize are trees and sod used by landscapers.

Class A product can be used right away on anything, including fields that grow the fruits and vegetables you buy at the grocery store and serve for dinner.

That’s because, Peot says, in the Cambi, “All the pathogens are completely obliterated.”

“Our product has these super-elevated levels of these naturally occurring, extremely important plant hormones,” Peot said.

It is a more environmentally sound choice than the chemical fertilizer alternatives. In the raw, the class A product is so potent it needs to be cut with other materials before it is used to fertilize crops.

“We can blend this with sawdust and sand and make a topsoil substitute for use in green infrastructure projects,” Peot said. “We’re still going to go to farms while we try to build the market for this product.”

Hawkins, D.C. Water’s general manager, chimed in: “It’s clean, organic fertilizer. Conceivably, we could sell this product at Home Depot. ”

Unlike most innovations in waste treatment locally and nationwide, this project was not mandated by a federal court order. D.C. Water’s board decided it was a worthwhile investment of ratepayers’ money.

“This was one of the easier $500 million decisions that we’ll ever ask the board to make,” Hawkins said, ticking off the value: a savings in electrical costs of about $10 million a year; lowering the cost of hauling away treated waste; the potential to generate a profit by selling the product; a reduction by one third in the plant’s carbon footprint; and one more critical virtue.

For about three days a month ago, residents of part of Northwest Washington were told to boil their drinking water for fear it might be contaminated. That scare was caused by a power problem that shut down a pumping station.

“It wasn’t Pepco’s problem. It was internal to us,” Hawkins said. “We have great fears here about what would happen if there was a catastrophic power failure and Blue Plains stopped.”

Generating power internally will provide enough juice to keep the basics running, were that to happen, he said.

“This is the rare combination of both environmentally and economically positive,” Peot said.